It is to pay the utmost respect to food.

It means to do the everyday work, cooking, with courtesy.

Sakai is the home of Japanese knife forging, the 600-year-old tradition.

And it is our mission to bring the sharpness nurtured here to today’s kitchens.

Since its foundation in 1969, Baba Cutlery Works is committed to Monozukuri, handcraft of highest quality.

Always have, always will, not depending on the well-established name.

Beyond tradition. For all the people in the world who love cooking.

In Japanese, the character meaning “eat” (食) is composed of the characters meaning “people” (人) and “good” (良). As this suggests, we think delicious meals make people smile and healthy.

Cutting process is at the beginning of such “eating” activity, and it is our desire to make this activity comfortable and stress-free.

In the world of washoku, or Japanese cuisine, it is said “whether you make the most of ingredients or spoil them depends on your knife.”

That’s because how you cut foods changes the texture, which contributes to taste of the meal.

Satisfying sharpness for cooks who really care for eaters while holding a knife.

Because we aspire to continuously spread the appeal of authentic Sakai forged knives to the world, it is also our important mission to pass down the traditional skill and technique to the next generation.

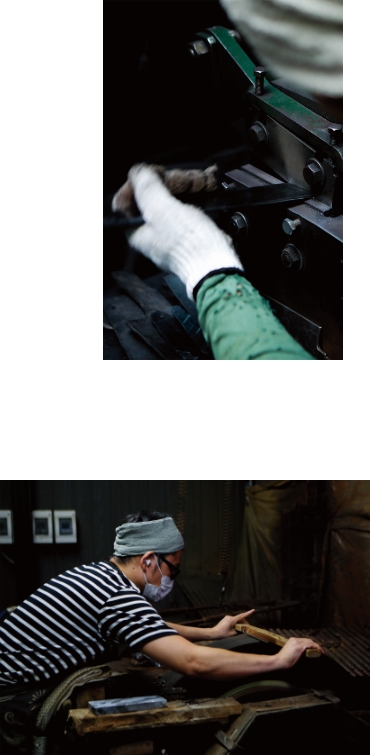

Blacksmiths hammer forge steel. Sharpeners delicately create edges.

Working together in a relationship of trust to pursue even higher standard – this is our ethic.

We have conducted close inspections of malfunctioning blades and shared the result with the craftsmen to increase the accuracy of forging and sharpening.

Such efforts at improvement give us full confidence in the quality of our own products.

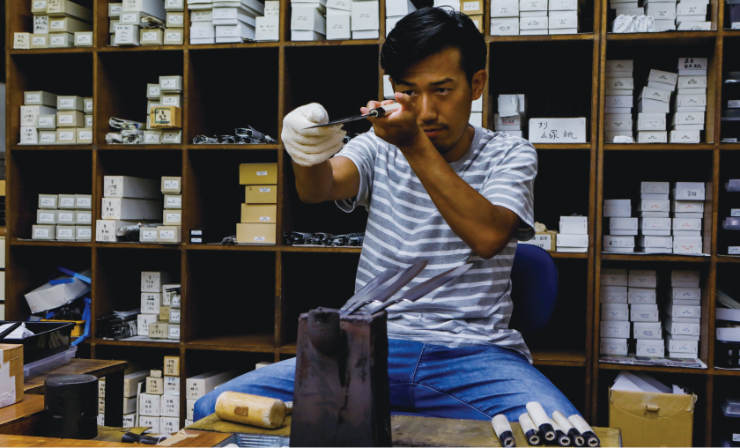

While more and more people around the world come to appreciate the genuine quality of Sakai forged knives, Sakai is suffering from aging of skilled craftsmen and lack of successors.

This led us to establish a sharpening workshop in 2017, so that we can train craftsmen by ourselves, not just placing orders to already highly skilled craftsmen.

Young craftsmen are untiringly honing their skills here, where they can learn from masters and devote themselves to genuine Monozukuri.